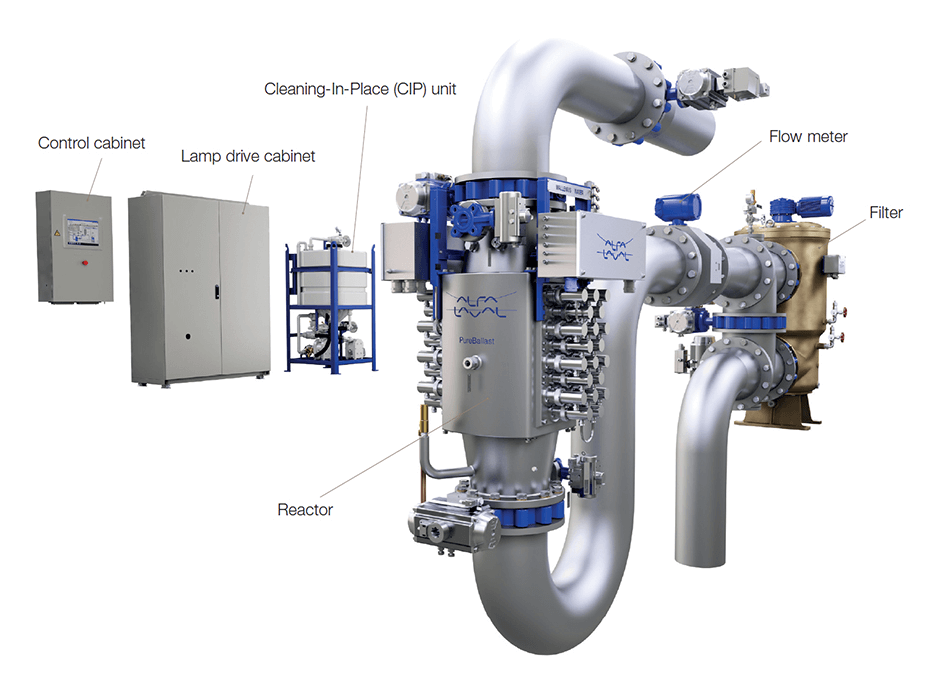

PureBallast 3 combines initial filtration with enhanced UV treatment in a specially designed reactor.

The main treatment process, occurs within an enhanced UV reactor. The reactor has a flow-optimized interior that ensures high turbulence and the concentration of the UV dose.

The medium-pressure UV lamps within the reactor employ specially designed lamp sleeves of synthetic quartz. These unique sleeves support transmission of a broader wavelength spectrum and provide more UV light during disinfection. Combined with the reactor’s internal design, this ensures optimal UV dosage and low energy consumption.

Supporting the reactor is a filter stage, used to remove any larger organisms and particles prior to biological disinfection. This improves the quality of water for treatment, especially when operating in cloudy coastal waters and fresh water.

In combination with the reactor, the effective basket filter design enables full-flow treatment of fresh, brackish and marine water with UV transmittance as low as 42%.

The fully automated system ballasting process, when starting, it undergoes a brief start-up sequence. When ballasting begins, the incoming ballast water first passes through the filter stage. This removes any larger organisms and particles, which improves the quality of the water for treatment. The filter stage is of benefit for operation in cloudy coastal waters and fresh water. After filtration the water continues through the reactor stage, where it is disinfected by means of enhanced UV before entering the ballast water tanks.

Once ballasting is completed, the filter stage is filled with fresh water and a Cleaning-In-Place (CIP) cycle is prompted for the reactor stage. The CIP cycle should be performed within 30 hours. The reactor stage is rinsed with fresh water at the beginning of the CIP cycle and filled with fresh water upon its completion.

The deballasting process is the same as the ballasting process. However, the filter stage is bypassed during deballasting since the water has already been filtered. After leaving the ballast water tanks, the outgoing ballast water passes through the reactor stage to eliminate any regrowth of microorganisms that may have occurred in transit. Having thus been disinfected to the established limits, it is discharged into the receiving water at the deballasting site.

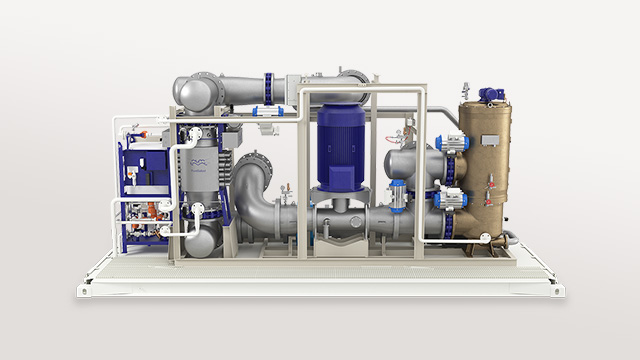

is a skid-mounted solution for smaller ballast water flows. Installation is easy due to the small footprint and minimized pipework.

Ballast flow 32-300 m3/h

is the ideal choice for most vessels. Delivered as loose components, it maximizes space savings and installation flexibility

Ballast flow 32-1000 m3/h

Provides widest range of reactor configurations and technical opportunities on vessels with non-hazardous environments.

Ballast flow 500-3000 m3/h

gives vessels with explosive environments redundant safety features and high flexibility. The power supply can be placed outside the hazardous zone.

Ballast flow 250-3000 m3/h

If your tanker uses submersible cargo pumps, you have maximum space for money-making cargo. But without a pump room, there’s no internal space for a ballast water treatment system. Alfa Laval PureBallast 3 Ex deckhouses make it easy to install on the weather deck, providing a complete, pre-assembled solution for tanker needs – including an integrated booster pump unit. Durable and purpose-designed, they safeguard compliance by protecting your PureBallast 3 Ex system throughout its lifetime.

PureBallast 3 Ex systems are available for flows of 250–3000 m3/h, with dual systems providing coverage for up to 6000 m3/h. They can be supplied in range of Ex configurations according to ATEX and IECEx, Zone 1, IIC and T4. Design is simplified by the flexible placement of the lamp drive cabinets, which can be located outside the hazardous zone and up to 150 m away from the reactors they serve.

Redundant safety features, such as the connection of the reactor temperature and level sensors via relays that bypass the PLC, increase safety in operation.

If your vessel is a bulker, you probably load cargo at twice the rate you unload it. If so, you deballast at twice the speed of ballasting. That gives you an opportunity to save. A PureBallast 3 bulker-fit configuration adjusts the UV reactor and filter capacities, so that you install only what a bulker needs for compliance. Not only does it create a smaller system footprint, it also lowers your investment and operating costs.

PureBallast 3 documentation for shipyards and other installing parties is divided into:

Direct assistance from Alfa Laval is also available to aid design and planning, as well as in the installation and commissioning processes.

Download Alfa Laval’s ballast water management resources to learn more about PureBallast 3 and how it compares to other available treatment technologies. To obtain design and installation documentation or more information, please contact Alfa Laval.