As of 1st June 2022, biological commissioning testing is required after installing a ballast water treatment system (BWTS). To show that the whole installation performs as it should, an independent lab must take and analyse water samples as part of the commissioning survey. You as the shipowner are responsible, but we can help you make sure that all goes well. Learn how to succeed with biological commissioning testing and let us support you when testing Alfa Laval PureBallast 3 installations.

“Biological commissioning testing, or commissioning sampling as it’s sometimes called, answers the demands of shipowners who want to be certain of ballast water treatment compliance. As this page explains, it ensures that ballast water treatment system installations actually perform according to type approval. My colleagues and I are ready to help you succeed in this new process, so please don’t hesitate to get in touch.”

Håkan Persson, Alfa Laval Global Service Sales & Business Development

The reasons and responsibilities for biological commissioning testing haven’t always been clear. Our white paper explains it all, including these takeaways:

1. The testing evaluates the specific installation, not the BWTS type approval

2. You are responsible for the testing, not your BWTS supplier

3. Failure means fault-finding, corrections and retesting at additional cost

4. Your BWTS supplier can’t do the sampling or analysis but can provide advice and practical support to help you succeed

As of 1st June 2022, biological commissioning testing is mandatory during the commissioning of ballast water treatment system installations. Unlike type approval, which validates the ballast water treatment system design, biological commissioning testing validates the specific system installation – including the tanks, pipes, valves and pumps. Water samples must be collected and analysed by an independent lab to show that the whole installation provides compliant performance.

As the shipowner, you’re responsible for biological commissioning testing. It’s not part of the system’s technical commissioning, nor can the system supplier assist with sampling and analysis. However, the supplier can support you in preparing, choosing a lab and ensuring proper operation of your ballast water treatment system. That can make the difference between leaving the shipyard compliant or having to perform fault-finding, corrections and retesting at extra cost.

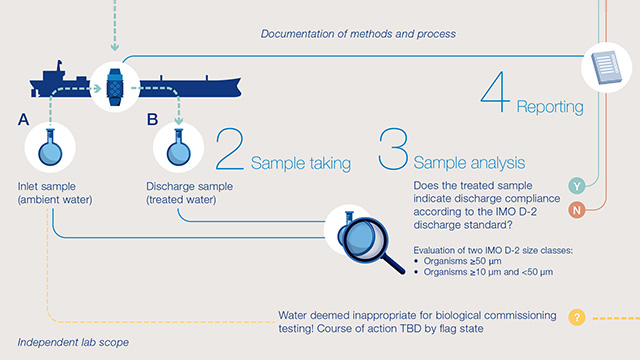

Biological commissioning testing is defined step-by-step in BWM.2/Circ.70/Rev.1, Guidance for the commissioning testing of ballast water management systems. The key steps – water sampling and analysis – must be performed by an independent lab. This infographic will help you understand the testing process and the potential outcomes.

Since biological commissioning testing evaluates the entire ballast water treatment system installation, even a small problem in a tank or pipe can lead to failure. But the most likely causes of failure are also the easiest to avoid. Making correct choices and preparations – even before you install – lays the groundwork for success. Learn how to get it right in this infographic.

You as the shipowner are responsible for biological commissioning testing and its consequences, but that doesn’t mean that you’re on your own. We’re ready to support you with installations of our own ballast water treatment solution, Alfa Laval PureBallast 3.

As a first step, contact us below to get our free knowledge pack, which includes:

Naturally, you can get further and deeper support from our PureBallast service experts. Simply get in touch and we’ll tell you more.

We’ve gathered some common questions about biological commissioning testing of ballast water treatment system installations. If you don’t find your answer here (or elsewhere on this page), try downloading our white paper or simply contact us.

The type approval says that your system’s design is proven to meet the IMO D-2 discharge requirements. But biological commissioning testing isn’t about the design. It’s about the specific installation on your vessel, including the tanks, pipework and valves. The testing verifies that your specific installation delivers performance matching the type approval.

No. Your supplier’s scope is the ballast water treatment system itself, and that responsibility ends with the system’s technical commissioning. Biological commissioning testing evaluates the whole installation, including components well beyond the system delivery. You as the shipowner are responsible for biological commissioning testing, although your BWTS supplier may be able to provide additional support services.

No, because the water sampling and analysis must be conducted by an independent lab. However, your supplier may offer valuable support, such as checklists and other resources to help you prepare. The regulation even leaves room for the possibility of having a service engineer on board during testing to help inexperienced crews avoid mistakes.

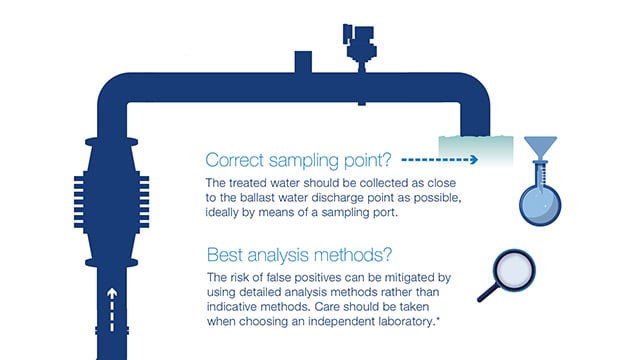

Yes and no. Your classification society may have a list of approved service providers that you need to choose from. Even if that’s not the case, you’ll want a qualified lab that uses the most favourable analysis methods. (See our white paper for more detail.) Your BWTS supplier may be able to make lab recommendations or support your selection in other ways.

In most cases, you’ll spend additional time and money on fault-finding, corrections and retesting. If the cause is self-evident, for example if the ambient water at the shipyard falls outside the System Design Limitations (SDL) of your BWTS, you may receive a short-term certificate from the flag administration. But even if you do, you’ll need to retest elsewhere within a few months. Our white paper explains more.

Let us know how we can assist you. Our experts are ready to explain biological commissioning testing and to help you succeed with the testing of Alfa Laval PureBallast 3 installations.