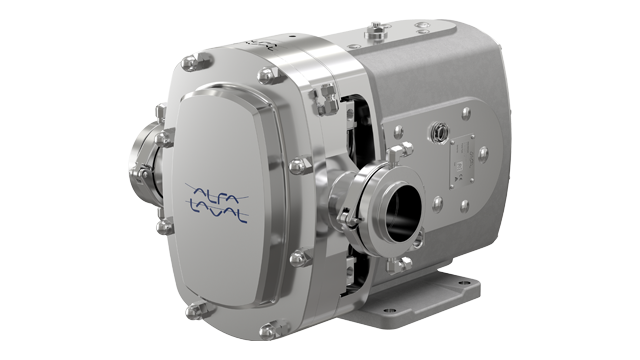

DuraCirc® Aseptic

The Alfa Laval DuraCirc® Aseptic is a revolutionary circumferential piston pump for aseptic applications. It delivers the perfect balance of durability, reliability, high efficiency and superior hygienic performance. Combined with a broad range of flow rates and pressures along with capabilities for simple service, DuraCirc® Aseptic keeps your processes up and running.

No more compromises: Best-in-class offering for supreme performance, superior hygiene and simpler service – all in the same pump

- Optimized for high volumetric efficiency, ensuring cost-effective pump selection and high product quality

- Hygienic design compliant with global standards, including EHEDG and 3-A

- Reliable, long-term operation thanks to durable, robust, heavy-duty, all-stainless steel construction

- Easy to service and maintain with fully interchangeable spare parts

- Truly aseptic with the ability to provide a steam barrier on all interfaces between the product media and the outside atmosphere

Pump performance, hygienic design and ease of service are essential to hygienic processes. The Alfa Laval DuraCirc® Aseptic circumferential piston pump (CPP) delivers it all – high volumetric efficiency, EHEDG and 3-A conformance, and quick and easy service. DuraCirc® Aseptic is engineered for aseptic process applications in the dairy, food and beverage industries, primarily for packaging where extended shelf life is required.

For a cost-effective pump selection, the pumps come in five models, capable of flow rates up to 103 m3/h (453 gpm) and pressures up to 25 bar (363 psi).

Simplify service in terms of complexity and time with user-friendly features including a truly front-loading, self-setting single mechanical seal, use of a single long-life oil lubricant, and external shimming.

How does the DuraCirc Aseptic circumferential piston pump work

The DuraCirc® Aseptic construction features two rotors, housed within a pumping chamber, known as a rotorcase, with each rotor located on a shaft held rigidly within a gearcase. The two rotors are timed via timing gears in the gearcase, which along with shimming, ensures no rotor or rotor case contact. Rotor/shaft drive is typicially provided via geared electric motor.

Due to the close internal running clearance within the pumping chamber, the rotation of the rotors continuously generates a partial vacuum in the suction port of the pump as the rotors unmesh. This results in a localized pressure drop, which allows fluid to enter the pump. The fluid is then transported around the channel by the rotor wings; the pressure generated as the rotor wings re-mesh forces the fluid out of the discharge port of the pump.

Servis

Our dedicated Global Service Network supports you with parts and expertise, wherever you are, whenever you need it. By ensuring greater uptime, availability and optimization, we help bring you peace of mind, and maximize your return on investment. We can work with you to integrate our services into an Alfa Laval Service Agreement for predictable and worry-free operations.

Learn more about our service offer Troubleshooting

Serial number search Certification

Please contact us with any queries or questions.

Navrhnuté pre väčšiu odolnosť, spoľahlivosť a efektivitu na rozšírenie hraníc výkonu

Supreme Performance

Designed with close pump head clearances, the DuraCirc® Aseptic pump maximizes volumetric efficiency and process yield. Five models offer a wide performance envelope with flow rate capabilities up to 103 m3/hr (453 gpm) and operating pressures up to 25 bar (363 psi). This makes optimal pump sizing and selection easy, thereby reducing capital costs and increasing process flexibility.

Based on a robust, reliable design, DuraCirc® Aseptic features include:

- Advanced port and pump-head geometry, providing a very low NPSHr characteristic. This significantly reduces cavitation risk and maintains pump and media integrity whilst increasing process flexibility in challenging applications

- Long-life, heavy-duty bearings, supporting rigid shafts located in a solid stainless steel gearcase, which reduce shaft movement and allow close pump-head clearances. This minimizes pump-head contact and ensures process uptime

- A modular seal design, which makes seal conversion easy without requiring re-machining or additional flush housings, should the process application change

- An optional retrofit port, the DuraCirc® Uni-Fit, enabling easy, direct replacement of existing circumferential piston pumps from both Alfa Laval and other brands, without requiring pipework modification in existing process systems

Produkt spoľahlivo spĺňa hygienické požiadavky odvetvia a zaisťuje integritu vašich procesov a

kvalitu vašich výrobkov

Superior Hygiene

The all-stainless-steel DuraCirc® Aseptic is certified to meet global standards for hygienic design, including EHEDG and 3-A. In contrast to many other circumferential piston pump brands, the DuraCirc® Aseptic provides both excellent cleanability and high volumetric efficiency.

Features that reduce the risk of contamination include:

- Profiled, product-wetted elastomers that are FDA-compliant and have a defined compression, thereby eliminating crevices and dead zones

- A robust gearcase with optimally positioned heavy-duty bearings that support large diameter shafts, which minimize pump-head contact, thereby reducing the risk of media contamination

- An all-stainless steel construction suitable for hygienic washdown, ensuring a cleaner environment

- Long-lasting, FDA-compliant gearbox lubricant

- Ability to introduce a steam barrier on all media/atmosphere interfaces, including front cover, ports and mechanical seals

Vďaka inovatívnym dizajnovým funkciám je údržba rýchlejšia a ľahšia, čím sa zvyšuje prevádzkový čas

Simpler Service

Increase process uptime and make service faster and easier with innovative DuraCirc® Aseptic design features. Perform standard maintenance procedures quickly and simply, without requiring gearbox disassembly, component re-work, or complex pump re-build procedures.

Features include:

- A truly front-loading, self-setting, single mechanical seal for fast, in-situ seal replacement, without having to remove the pump from the process line

- Quick, easy replacement of rotors or rotor case in the unlikely event replacement is required

- Easy-to-access, external shimming outside the rotorcase instead of inside the gearbox

- Fully interchangeable spare parts

- Long-life bearings, offering tens of thousands of hours of operation

- A single, long-life, FDA-approved gearbox lubricant with an extended 3,000-hour change interval

DuraCirc® Aseptic brochure

Discover how the DuraCirc® Aseptic offers Supreme Performance, Superior Hygiene and Simpler Service.

Jednoduché sledovanie stavu hygienických čerpadiel

Alfa Laval CM monitoruje prevádzkový stav rotačných zariadení, ako sú napríklad čerpadlá

360° videá zo servisu a údržby

Ako demontovať a namontovať mokrú časť

Mohlo by vás zaujímať...

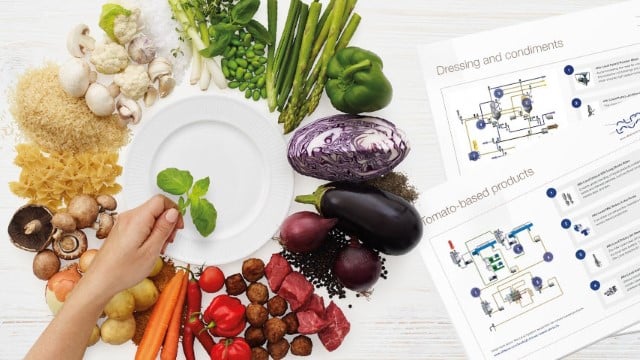

Myslíme na jedlo

Hygienické zariadenia Alfa Laval kombinujú vysokú výkonnosť s jemným zaobchádzaním, čím sa chránia citlivé zložky v médiách. Riadia sa najnovšími trendmi v potravinárskom priemysle a riešia štyri kľúčové požiadavky: dodávku potravinárskych produktov spotrebiteľom za výhodné ceny, maximálne využitie surovín, zníženie podielu odpadu a emisií a dodávku bezpečných a hygienických potravinárskych produktov.

Subscribe near Newsletter

Stay updated on important sustainability issues and opportunities in your industry and processes!