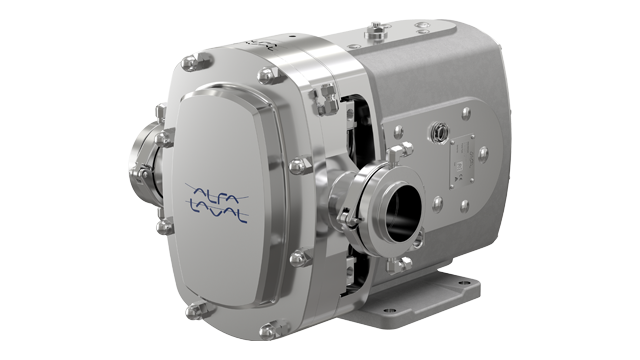

DuraCirc® Aseptic

The Alfa Laval DuraCirc® Aseptic is a revolutionary circumferential piston pump for aseptic applications. It delivers the perfect balance of durability, reliability, high efficiency and superior hygienic performance. Combined with a broad range of flow rates and pressures along with capabilities for simple service, DuraCirc® Aseptic keeps your processes up and running.

No more compromises: Best-in-class offering for supreme performance, superior hygiene and simpler service – all in the same pump

- Optimized for high volumetric efficiency, ensuring cost-effective pump selection and high product quality

- Hygienic design compliant with global standards, including EHEDG and 3-A

- Reliable, long-term operation thanks to durable, robust, heavy-duty, all-stainless steel construction

- Easy to service and maintain with fully interchangeable spare parts

- Truly aseptic with the ability to provide a steam barrier on all interfaces between the product media and the outside atmosphere

Pump performance, hygienic design and ease of service are essential to hygienic processes. The Alfa Laval DuraCirc® Aseptic circumferential piston pump (CPP) delivers it all – high volumetric efficiency, EHEDG and 3-A conformance, and quick and easy service. DuraCirc® Aseptic is engineered for aseptic process applications in the dairy, food and beverage industries, primarily for packaging where extended shelf life is required.

For a cost-effective pump selection, the pumps come in five models, capable of flow rates up to 103 m3/h (453 gpm) and pressures up to 25 bar (363 psi).

Simplify service in terms of complexity and time with user-friendly features including a truly front-loading, self-setting single mechanical seal, use of a single long-life oil lubricant, and external shimming.

How does the DuraCirc Aseptic circumferential piston pump work

The Alfa Laval DuraCirc® Aseptic construction features two rotors, housed within a pumping chamber, known as a rotorcase, with each rotor located on a shaft held rigidly within a gearcase. As a leading circumferential pump, the DuraCirc® is designed for demanding aseptic pumps applications. The two rotors are timed via timing gears in the gearcase, which along with shimming, ensures no rotor or rotor case contact. Rotor/shaft drive is typicially provided via geared electric motor.

Due to the close internal running clearance within the pumping chamber, the rotation of the rotors continuously generates a partial vacuum in the suction port of the pump as the rotors unmesh. This results in a localized pressure drop, which allows fluid to enter the pump. The fluid is then transported around the channel by the rotor wings; the pressure generated as the rotor wings re-mesh forces the fluid out of the discharge port of the pump.

Alfa Laval DuraCirc® aseptic pumps are EHEDG certified, ensuring the highest standards of hygiene and safety for sensitive applications. These aseptic pumps are ideal for industries requiring reliable, high-performance circumferential pumps.

Praktický katalóg

Praktický katalóg hygienických výrobkov obsahuje informácie o výrobkoch, odkazy na animácie, brožúry a objednávkové zoznamy.

Portál CAD

Portál CAD spoločnosti Alfa Laval je základnou platformou na stiahnutie podrobných informácií o výrobku, 2D výkresov a 3D modelov výrobkov.

Servis

Naša špecializovaná globálna servisná sieť vám poskytne náhradné diely a odborné znalosti kdekoľvek a kedykoľvek ich budete potrebovať. Zabezpečením vyššej prevádzkyschopnosti, dostupnosti a optimalizácie vám pomáhame zaistiť pokoj a maximalizovať návratnosť investícií. Môžeme s vami spolupracovať na integrácii našich služieb do vašej servisnej zmluvy so spoločnosťou Alfa Laval, aby ste dosiahli predvídateľnú a bezstarostnú prevádzku.

Získajte viac informácií o našej ponuke služieb Odstraňovania porúch

Náhradné diely Technická podpora

Vyhľadanie sériového čísla Certifikácia

V prípade akýchkoľvek otázok nás prosím kontaktujte.

Navrhnuté pre väčšiu odolnosť, spoľahlivosť a efektivitu na rozšírenie hraníc výkonu

Supreme Performance

Designed with close pump head clearances, the DuraCirc® Aseptic pump maximizes volumetric efficiency and process yield. Five models offer a wide performance envelope with flow rate capabilities up to 103 m3/hr (453 gpm) and operating pressures up to 25 bar (363 psi). This makes optimal pump sizing and selection easy, thereby reducing capital costs and increasing process flexibility.

Based on a robust, reliable design, DuraCirc® Aseptic features include:

- Advanced port and pump-head geometry, providing a very low NPSHr characteristic. This significantly reduces cavitation risk and maintains pump and media integrity whilst increasing process flexibility in challenging applications

- Long-life, heavy-duty bearings, supporting rigid shafts located in a solid stainless steel gearcase, which reduce shaft movement and allow close pump-head clearances. This minimizes pump-head contact and ensures process uptime

- A modular seal design, which makes seal conversion easy without requiring re-machining or additional flush housings, should the process application change

- An optional retrofit port, the DuraCirc® Uni-Fit, enabling easy, direct replacement of existing circumferential piston pumps from both Alfa Laval and other brands, without requiring pipework modification in existing process systems

Produkt spoľahlivo spĺňa hygienické požiadavky odvetvia a zaisťuje integritu vašich procesov a

kvalitu vašich výrobkov

Superior Hygiene

The all-stainless-steel DuraCirc® Aseptic is certified to meet global standards for hygienic design, including EHEDG and 3-A. In contrast to many other circumferential piston pump brands, the DuraCirc® Aseptic provides both excellent cleanability and high volumetric efficiency.

Features that reduce the risk of contamination include:

- Profiled, product-wetted elastomers that are FDA-compliant and have a defined compression, thereby eliminating crevices and dead zones

- A robust gearcase with optimally positioned heavy-duty bearings that support large diameter shafts, which minimize pump-head contact, thereby reducing the risk of media contamination

- An all-stainless steel construction suitable for hygienic washdown, ensuring a cleaner environment

- Long-lasting, FDA-compliant gearbox lubricant

- Ability to introduce a steam barrier on all media/atmosphere interfaces, including front cover, ports and mechanical seals

Vďaka inovatívnym dizajnovým funkciám je údržba rýchlejšia a ľahšia, čím sa zvyšuje prevádzkový čas

Simpler Service

Increase process uptime and make service faster and easier with innovative DuraCirc® Aseptic design features. Perform standard maintenance procedures quickly and simply, without requiring gearbox disassembly, component re-work, or complex pump re-build procedures.

Features include:

- A truly front-loading, self-setting, single mechanical seal for fast, in-situ seal replacement, without having to remove the pump from the process line

- Quick, easy replacement of rotors or rotor case in the unlikely event replacement is required

- Easy-to-access, external shimming outside the rotorcase instead of inside the gearbox

- Fully interchangeable spare parts

- Long-life bearings, offering tens of thousands of hours of operation

- A single, long-life, FDA-approved gearbox lubricant with an extended 3,000-hour change interval

DuraCirc® Aseptic brochure

Discover how the DuraCirc® Aseptic offers Supreme Performance, Superior Hygiene and Simpler Service.

Jednoduché sledovanie stavu hygienických čerpadiel

Alfa Laval CM monitoruje prevádzkový stav rotačných zariadení, ako sú napríklad čerpadlá

Visit the Application & Innovation Centre

Do you want to identify the optimal equipment for the job and discover tangible savings before deciding on upgrades? In the Alfa Laval Application & Innovation Centre, you can do just that.

Optimize™ by Alfa Laval

Optimize™ by Alfa Laval boosts your existing processes and enables up to 90% savings on water, energy and chemicals with only small and no-risk investments.

360° videá zo servisu a údržby

Ako demontovať a namontovať mokrú časť

Mohlo by vás zaujímať...

Myslíme na jedlo

Hygienické zariadenia Alfa Laval kombinujú vysokú výkonnosť s jemným zaobchádzaním, čím sa chránia citlivé zložky v médiách. Riadia sa najnovšími trendmi v potravinárskom priemysle a riešia štyri kľúčové požiadavky: dodávku potravinárskych produktov spotrebiteľom za výhodné ceny, maximálne využitie surovín, zníženie podielu odpadu a emisií a dodávku bezpečných a hygienických potravinárskych produktov.

Prihláste sa na odber newslettera Near

Buďte informovaní o dôležitých otázkach udržateľnosti a príležitostiach vo vašom odvetví a procesoch!

Animácie

Navštívte stránku s animáciami a pozrite si vnútro produktu, aby ste videli a pochopili, ako funguje.