PureVent

Optimize engine reliability with Alfa Laval PureVent 2.0. This centrifugal separator efficiently removes up to 99.9% of oil mist from crankcase blow-by, preventing excessive crankcase pressure and minimizing oil contamination. Maintain stable engine operation and reduce maintenance needs.

Superior crankcase gas cleaning for engine performance

- Outstanding cleaning efficiency - removes up to 99,9% of oil mist, outperforms traditional cyclones, air traps, and filters

- Enables responsible release of virtually oil-free air into the atmosphere. Recovered oil can be reused.

- Long service intervals (up to 16,000 hours) - less maintenance, no frequent filter changes or hazardous waste

- Flexible design to fit specific needs onboard or at power plants

- Proven performance in demanding applications, improving air quality and reducing lube oil consumption

Crankcase emissions create challenges—oil mist pollutes the sea and soils engine spaces and decks.

Alfa Laval PureVent 2.0 tackles this with high-speed centrifugal separation, removing oil mist and particles from crankcase gas.

You can then safely release the cleaned gas into the atmosphere or recirculate it to the turbocharger.

Learn about its easy installation, minimal maintenance, suitability for various applications.

Features that set PureVent apart

High-speed disc stack centrifugation (7200 rpm)

The graph shows the grade efficiency of oil mist separation at flows of 100 m3/h and 200m3/h

The advanced technology delivers outstanding and steady cleaning efficiency, removing up to 99.9% of oil mist from crankcase gas. That means cleaner air output and less risk of engine pressure build-up.

Flexible design

Open and closed system compatibility, whether releasing cleaned gas to the atmosphere or recirculating it to the turbocharger, PureVent 2.0 keeps engine spaces cleaner and prevents turbocharger fouling. This flexibility ensures optimal operation in both power plant and marine applications.

Scalable setup (option)

The system can easily run two units in parallel for flows above 200 m³/h, managed by a shared variable frequency drive (VFD), maintaining stable pressure and separation efficiency even in demanding environments. This means fewer maintenance interruptions and consistent engine protection.

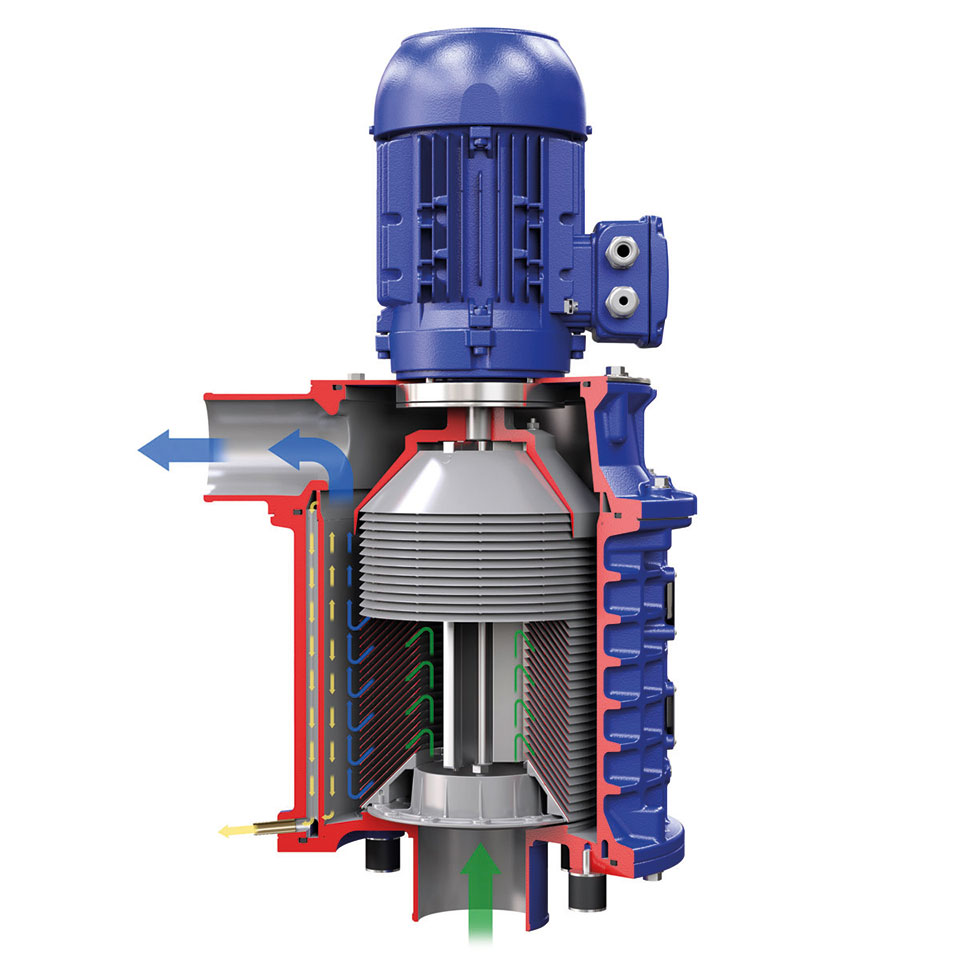

How it works

PureVent 2.0 uses high-speed centrifugation to remove oil mist, soot and unburned fuel from crankcase gas.

The separator unit has a stack of 185 rotating discs made from lightweight polymer. Crankcase gas enters at the bottom and passes into the disc stack. Centrifugal force presses oil and soot out. This leaves air virtually oil-free, so you can responsibly release it into the atmosphere.

For enhanced environmental performance, the collected oil can be recirculated through the separator and used again, in example in the engine lubrication system.

The collected oil may also be drained for use in shipboard incinerators or stored for proper disposal.

Select your ideal crankcase ventilation system design:

Open design – releases oil-free crankcase gas directly into the atmosphere

Closed design – re-circulates clean gas to the turbocharger, eliminating all crankcase emissions and the risk of turbocharger fouling

How PureVent cleans crankcase gas from diesel engines at engine power plants

How PureVent cleans crankcase gas onboard vessels in example cruise ships

Real life experience with PureVent for crankcase ventilation

Capturing oil mist from the engine blow-by is a clean win for EPASA

Centrais Elétricas de Paraíba, or EPASA,is the owner of two diesel power plants near João Pessoa, a coastal city at Brazil’s eastern tip. With a total installed capacity of around 340 MW, the plants form one of the largest thermoelectric power facilities in the region. EPASA keeps a watchful eye on their environmental impact and operating efficiency, and this was the reason for installing 40 units of Alfa Laval PureVent 2.0. With this unique air separator, the plants have eliminated an oily environment and reduced lube oil consumption.

Servisná sieť pre lodný priemysel

Naša špecializovaná servisná sieť pre lodný priemysel vás podporuje prostredníctvom náhradných dielov a odborných znalostí, kdekoľvek sa nachádzate a kedykoľvek ich potrebujete. Zabezpečením dlhšej bezporuchovej prevádzky, vyššej dostupnosti a väčšej optimalizácie vám prinášame pokoj a pomáhame vám maximalizovať návratnosť investícií.

Ako vám môžeme pomôcť?

Ak máte otázky alebo potrebujete servis, kontaktujte nás.

Ak potrebujete pohotovostnú službu pre lodný priemysel, volajte na číslo +46 4636 7700.