Pioneering positive impact in cell harvesting

Cell harvesting plays a critical role in biopharma processing, and the choice of separation technology has a substantial impact on overall performance. Alfa Laval is a pioneer in centrifugal separation for biopharma applications, offering well-proven, market-leading cell-harvesting technology. Our experts support you in selecting the optimal solution for your process, resulting in improved yield, shorter cycle times, reduced OPEX, and increased profitability.

Meeting the challenges of the biopharma industry

Rapid innovation is transforming the biopharma industry. Higher cell densities, advances in single-use processing, and the growing use of mammalian cell cultures are just a few examples of developments creating both opportunities and challenges for producers.

At Alfa Laval, we are at the forefront of cell harvesting technology. Regardless of process type, we help you select the optimal solution to fully leverage upstream and downstream innovations. This includes:

- Solutions that enable very high cell density processes.

- Cell harvesting systems that maximise yield and minimise downstream processing through gentle, low-lysis separation.

- Super-efficient single-use solutions that eliminate the need for primary filtration and significantly reduce plastic waste.

- Equipment designed for low water and energy consumption, supporting more sustainable operations.

- Systems that meet the highest hygiene standards, ensuring maximum patient safety.

Pioneers at work – The cell harvesting vodcast

Listen in as our biopharma experts share practical advice, strategic insights, and the latest developments from the frontline of biopharma innovation.

Episode 1 – "The proof is in the pudding"

Discover how single-use separators are revolutionizing the biopharma industry.

Coming soon: Episode 2 – "Set it and forget it"

Learn how to improve efficiency in your cell harvesting process.

A complete range of cell harvesting equipment

Stainless steel processes

Stainless steel processes

Alfa Laval offers an extensive portfolio of stainless-steel separators for biopharma production, including both steam-sterilisable and CIP-capable models. We provide application-optimised solutions for everything from mammalian cell cultures and microbial fermentation to vaccine and probiotics production.

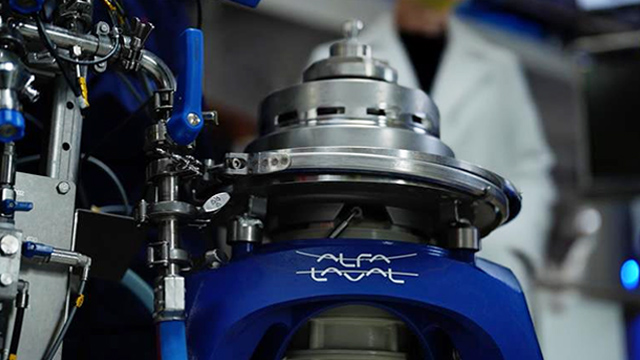

Single-use processes

Alfa Laval is leading the development of centrifugal separators for single-use processing. Introducing a separator into your process eliminates the need for primary depth filters, reduces product loss, shortens processing times, simplifies downstream operations, and dramatically reduces the amounts of solid waste.

Full support from our experts

Choosing the right cell harvesting separator requires careful consideration of factors such as cell type, concentration, fermentation broth characteristics, system capacity, and future scale-up plans.

At Alfa Laval, we understand these challenges. No matter the size of your operation or the cells you work with, our application specialists help you configure a separation system tailored to your process. We ensure your equipment meets all performance requirements and delivers reliable, long-term results.

Patient safety comes first

Our first priority is always the safety of the patients, and every detail of our biopharma separation systems is designed with this in mind. Our solutions comply with the highest manufacturing standards for hygiene, cleanability, traceability, documentation, system changes and validation. We have long experience of supplying centrifugal equipment to the pharmaceuticals industry and have the regulatory expertise and organizational tools to manage all requirements for cGMP compliance. We provide validations, certificates and documentation that comply with the most stringent industry demands. Our in-house Factory Acceptance Test (FAT) lab lets us validate each system before delivery and we can also provide additional validation services if required.

Key technologies for cell harvesting separators

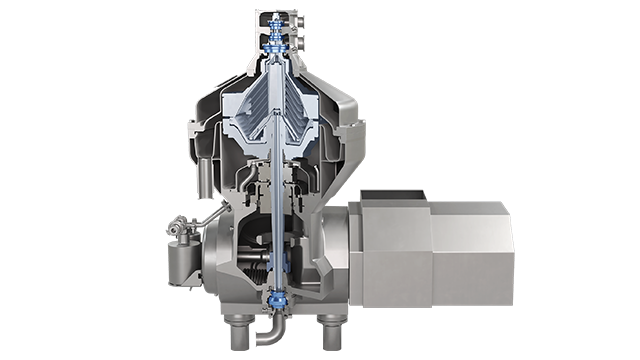

Improve separation performance with Hermetic Design™

Separators featuring Alfa Laval’s unique Hermetic Design are the ideal choice for harvesting shear-sensitive cells from fermentation broths. Gentle acceleration, combined with a fully air-tight design, minimises cell lysis and ensures outstanding separation performance, resulting in higher yield and optimised downstream processing.

Exceptional solids handling with TopStream™ / Bactofuge®

TopStream technology (also known as Bactofuge) enables gentle, continuous removal of solids from fermentation broths with high cell concentrations, without the risk of clogging. It improves separation efficiency and yield, while preserving cell integrity – a key advantage in applications where cell viability matters, such as probiotics and starter culture production.

Development of a single-use, hermetic centrifuge system

This whitepaper presents the development and validation of Alfa Laval’s single-use hermetic centrifuge system. Designed for harvesting mammalian cell cultures in high-density processes, the system enables gentle, efficient separation with high yields, even at very high cell densities.

This unique technology can significantly reduce filtration bottlenecks, improve downstream performance, and support production flexibility.

Service and maintenance

With Alfa Laval as your service partner, you have the full support of our global network of dedicated service experts. We offer a wide range of services spanning the entire lifetime of your separation system, such as upgrades that increase separation performance, monitoring systems and audits. Our experts train your operators to run and maintain your system in an optimal way to maximize its performance. When needed, our distribution network quickly supplies spare parts with all the necessary compliance certificates.

Service agreements

An Alfa Laval Service Agreement is a fully tailored service solution for your separator that maximizes equipment availability and performance. It ensures high process yield, consistent product quality, simplified GMP-related administration, and maximum patient safety, while minimizing the risk of out-of-specification batches. The agreement can include any Alfa Laval service and gives you full control of your maintenance costs, making budgeting easier and more accurate. We take care of all the planning and inform you well in advance of each service.

MB 20 / MB 20 Bactofuge – Ideal for lab and pilot-scale processes

Alfa Laval MB 20 and MB 20 Bactofuge are the optimal cell harvesting separators for lab and pilot-scale processes, delivering best-in-class performance. Featuring the same proven technologies found in Alfa Laval’s full-scale separators, they make it easy to scale up your process. Starting with MB 20, you ensure predictable results and a seamless transition as you scale up to larger production volumes.

Based on Alfa Laval’s unique Hermetic Design™, MB 20 enables gentle, high-efficiency separation of shear-sensitive cells. The MB 20 Bactofuge model adds continuous solids discharge, enabling reliable operation at very high cell densities.

Comprehensive testing opportunities

To facilitate your evaluation process, Alfa Laval offers extensive testing capabilities that allow you to verify performance under your own process conditions.

You can rent test equipment for on-site evaluation, enabling trials with your actual raw material and setup. Alternatively, you are welcome to our fully equipped test centre in Sweden, where you can explore new ideas, produce trial batches, or validate full-scale performance, all with the support of our biopharma experts.

Explore our innovations

Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.

> Learn more about our separator innovations