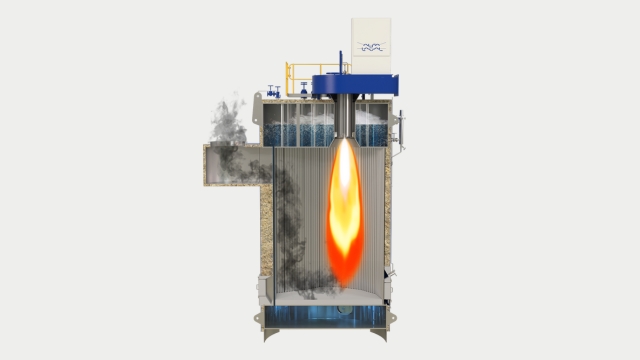

Oil/gas-fired steam boiler

Alfa Laval Aalborg steam boilers build on more than 100 years of boilermaking experience. Fired Aalborg boilers combine proven thermal design with effective, low-emission burner technology, which lets them deliver saturated or superheated steam with high efficiency and reliability. Thanks to furnace and tube designs that optimize durability as well as heat transfer, they provide lasting uptime and performance in a wide range of marine and industrial applications.

Benefits of Alfa Laval Aalborg steam boilers

- Flexibility to work with diverse fuels, pressure ranges and steam applications

- High thermal efficiency and reliable performance thanks to optimized furnaces and tubing

- Easy installation and integration with the help of compact designs

- Robust boiler construction that delivers long service life in demanding conditions

- Easy inspection and maintenance that keep efficiency high and downtime low

Through over a century of work with steam and heat generation, Alfa Laval has developed efficient and reliable boiler technology with high flexibility for modern demands.

What makes Alfa Laval Aalborg steam boilers different?

With proven thermal designs and state-of-the-art features, Alfa Laval Alborg boilers set the standard for steam production in marine applications and many industries.

Robust construction

High-quality materials and expertly welded shells and tubing ensure long-term structural integrity and safe operation. Built with over 100 years of insight into boiler operation, Aalborg boilers withstand both demanding environments and thermal cycling.

Optimized furnaces

The balanced furnace geometry of Aalborg boilers promotes efficient combustion, supporting a stable, reliable flame with low emissions. It also promotes efficiency by providing even heat distribution across the boiler’s heating surfaces.

Seamless burner integration

Aalborg burners are engineered for optimal performance with the boiler’s furnace design, ensuring stable and complete combustion. Steam or pressure atomization may be used, and most burners support dual-fuel or multi-fuel operations.

Maintainable efficiency

Features like cleanable tube arrangements and intelligent self-cleaning functions make it easy to keep Aalborg boilers efficient over time. Generous access possibilities for inspection and maintenance also reduce the downtime needed for routine service.

Multi-pass designs

Some Aalborg boilers feature multi-pass designs, in which the flue gas passes through the tube bundle multiple times. This provides a high level of heat transfer efficiency and supports consistent steam production under varying load conditions.

Compact design

Space-efficient Aalborg boilers have a small footprint and are designed for easy integration into boiler rooms and engine rooms without compromising performance. The boilers are generally delivered with burners and other fittings pre-mounted.

Marine boilers

Fuel-flexible and future proof, today’s Aalborg boiler platform supports all fuels in the marine transition, as well as hybrid operation with electricity. Ready-boiler configurations are available for new boilers, allowing later conversion for alternative fuels or shore power.

Industrial boilers

Aalborg boilers for industry ensure high-efficiency steam production in process and power applications. Most of them have a multi-pass design, which helps to maximize heat transfer. The Aalborg HPNC, which uses natural circulation, is specifically for food and dairy needs.

How it works

How fired steam boilers work

Steam boilers produce steam by transferring heat to water in a pressure vessel. In most cases, the heat is produced through combustion in the boiler furnace. But it can also be provided by electric heating elements, with hybrid boiler designs offering both possibilities.

During fired operation, the heat from fuel combustion is transferred to the furnace shell, mainly through radiation. Flue gases leaving the furnace enter vertical uptakes where the heat is transferred to boiler tubes, mainly through convection. The tube designs, such as pin tubes, spiral tubes or helix tubes, vary by boiler type. Some boilers also have a multi-pass design, which increases thermal efficiency by forcing the flue gases to pass through the tube section multiple times.

Heat transferred through the furnace shell or the tube walls evaporates the adjacent saturated water on the boiler’s water side. This causes steam bubbles to form. Because the steam bubbles have a much lower specific density than the water, they rise rapidly into the steam space, where the water and steam are separated. Depending on the boiler and application, the steam may be either saturated or superheated.

Servisná sieť pre lodný priemysel

Naša špecializovaná servisná sieť pre lodný priemysel vás podporuje prostredníctvom náhradných dielov a odborných znalostí, kdekoľvek sa nachádzate a kedykoľvek ich potrebujete. Zabezpečením dlhšej bezporuchovej prevádzky, vyššej dostupnosti a väčšej optimalizácie vám prinášame pokoj a pomáhame vám maximalizovať návratnosť investícií.

Ako vám môžeme pomôcť?

Ak máte otázky alebo potrebujete servis, kontaktujte nás.

Ak potrebujete pohotovostnú službu pre lodný priemysel, volajte na číslo +46 4636 7700.