PureBilge

Alfa Laval PureBilge is a fully automated centrifugal oily water separation system that treats bilge water onboard. It handles large volumes and can reduce oil content to below 5 ppm - well beyond the IMO’s 15 ppm requirement.

Reliable bilge water separation, compliance-ready by design

- Compact and modular. Easy to install. Saves time, space, and cost.

- Efficient single-stage process, less holding tank volume and more payload capacity.

- Low maintenance - fully automated, no chemicals, no disposable filters and minimal waste.

- Secure overboard discharge - password-protected, only authorized crew can release water overboard.

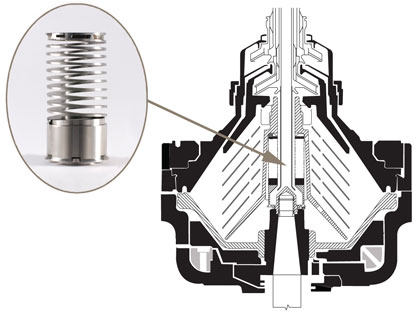

Alfa Laval PureBilge uses high-speed centrifugal separation technology to clean oily water/bilge. The patented XLrator spiral inlet prevents oil droplets from splitting and forming emulsions, improving separation efficiency. The system is also available in a smaller version - PureBilge Compact.

PureBilge Compact is built for vessels with lower treatment needs. It fits both new builds and retrofits.

No chemicals. No filters. Designed for 24/7 unmanned operation.

How it works

Bilge water treatment for real-life conditions

Bilge water isn’t just oil, water, and particles.

It’s a complex chemical mix that makes meeting discharge limits - especially 5 ppm - challenging in real-world conditions. Alfa Laval PureBilge is built to handle that complexity. It’s an oily water separator (OWS) that performs reliably, not just in tests, but out at sea.

Watch the video to see how

How PureBilge Works

PureBilge is a fully automated bilge water treatment system that combines pumping, preheating, and centrifugal separation to meet IMO discharge limits - even down to 5 ppm.

Oily water is filtered and heated before entering the separator, where it spins at 8,000 rpm to remove oil, emulsions, and solids. Clean water is discharged only if oil content is below the set limit; otherwise, it’s recirculated. The system features the patented XLrator inlet for efficient flow and now includes the EPC 70 control cabinet, offering advanced process control and built-in cybersecurity protection.

Features that set PureBilge apart

Fully automated

PureBilge integrates pumping, preheating, and high-speed centrifugal separation with full process control and monitoring—ensuring reliable, hands-free operation.

Compact and modular design

Its space-saving footprint and modular setup simplify installation and integration, reducing time and cost during setup and maintenance.

XLrator spiral inlet

The patented XLrator spiral inlet and 6,000 G centrifugal force enable uninterrupted, single-stage operation with superior oil-water separation—even under tough conditions.

Low OPEX

No chemicals, no disposable filters, minimal waste disposal, and automated control all contribute to significantly reduced maintenance and operating expenses.

Robust performance in harsh conditions

PureBilge maintains stable operation regardless of sea heave, oil shocks, or trace solids loading—ensuring consistent compliance and performance.

Secure discharge control

A password-protected switch ensures only authorized personnel can initiate overboard discharge, supporting strict environmental compliance and operational accountability.

PureBilge stories - compliance without compromise

Case stories and testimonials from vessels that rely on PureBilge for reliable bilge water treatment and safe overboard discharge

Centrifugal separation means oily water discharge compliance

With a fleet of greater than 100 vessels, Teekay is one of the major marine actors in today’s energy sector. The company takes no chances with environmental compliance, especially when it comes to oily water treatment. A large number of Teekay’s vessels rely on centrifugal separation and oily water treatment systems from Alfa Laval.

Replacing static OWS with Alfa Laval PureBilge Compact put an end to costly frustration

Tired of high filter costs and monitoring bilge water treatment? So was this European shipper – until Alfa Laval PureBilge Compact changed everything. Learn how centrifugal separation put an end to frustration with static, coalescer type oily water separation (OWS) systems.

Alfa Laval PureBilge oily water separator onboard Norwegian Breakaway

Norwegian Breakaway has taken a proactive approach towards environmental responsibility.

See how Alfa Laval PureBilge works onboard.

Alfa Laval recovers all reusable oil from oily wastewater and cuts waste disposal costs

When Atlantic Islands Electricity (AIE), a privately owned power station located on Madeira Island, needed new, more sustainable ways to optimize performance, the company turned to its current fuel-conditioning equipment supplier, Alfa Laval, for answers. With the combination of an Alfa Laval PureDry waste fuel recovery system and an Alfa Laval PureBilge oily water cleaning system, AIE now turns 45 tons of oily waste per month into 30 tons of cleaned water that can be released directly into the ocean and recovers 15 tons of usable fuel from oily waste.

Expert corner

Bilge water compliance issues

Persistent failures in oily water separator (OWS) systems—often linked to tampering and underinvestment in maintenance—signal deeper breakdowns in maritime compliance. This white paper examines why conventional bilge water treatment technologies fall short and how Alfa Laval PureBilge, with its high-speed centrifugal separation, offers a robust alternative proven to meet regulatory demands under real-life conditions.

Alfa Laval Meet the Experts: Shinya Tanehashi

Most oily water separators today rely on coalescer-type separation. While type-approved, these coalescer systems often struggle to meet the 15 ppm IMO discharge limit under real-life conditions. Learn how Alfa Laval PureBilge ensures reliable compliance without filters or chemicals in challenging marine environments.

Servisná sieť pre lodný priemysel

Naša špecializovaná servisná sieť pre lodný priemysel vás podporuje prostredníctvom náhradných dielov a odborných znalostí, kdekoľvek sa nachádzate a kedykoľvek ich potrebujete. Zabezpečením dlhšej bezporuchovej prevádzky, vyššej dostupnosti a väčšej optimalizácie vám prinášame pokoj a pomáhame vám maximalizovať návratnosť investícií.

Ako vám môžeme pomôcť?

Ak máte otázky alebo potrebujete servis, kontaktujte nás.

Ak potrebujete pohotovostnú službu pre lodný priemysel, volajte na číslo +46 4636 7700.